Contributions of Islamic scholars to the scientific enterprise: Chemistry, Pharmacology and Pharmacy

by Yasmeen Mahnaz Faruqi

Most educational systems, particularly those of Western countries, teach that industry was born in Europe and that the Industrial Revolution was the mother that delivered industrial mass production. Salim Al-Hassani, Chairman of FSTC and eminent expert in Islamic science and Muslim Heritage at large, challenges this view and presents an overview of the industrial and engineering processes which preceded the Industrial Revolution. Examining briefly the vast industry which stretched from China to Spain during the Muslim Civilisation (eighth-seventeenth centuries), he presents an overview of some randomly selected aspects of Muslim industrial production which highlights not only the Islamic antecedents of many processes and products widespread in our modern industrial system, but also how erroneous is the opinion that industrial production was alien to Islamic society.

Professor Salim T S Al-Hassani*

This article is an expanded and revised version of a research article published as: Salim T S Al-Hassani, “1000 Years of Missing Industrial History” in A Shared Legacy: Islamic Science East and West: Homage to professor I. M. Vallicrosa, edited by Emilia Calvo, Mercè Comes, Roser Puig and Mònica Rius, Barcelona: Universitat de Barcelona, 2008, pp. 57-82.

Table of contents

1. Setting the stage for the recovery of the neglected history of pre-modern industry

1.1. Prologue

1.2. The missing history of Islamic industry

1.3. Thriving cities of industry in the Andalus

2. Aspects of the industrial production in Islamic civilisation

2.1. Examples: part 1

2.1.1. Steel

2.1.2. Petroleum

2.1.3. Mining and metallurgy

2.1.4. Chemistry

2.1.5. Industrial production of paper

2.2.1. Pottery

2.2.2. Ceramics

2.2.3. Glass

2.2.4. Textile

2.2.5. Ship building

2.2.6. Agriculture and farming

3. Science, management and industrial growth

4. References and bibliography

4.1. Articles published on www.MuslimHeritage.com

4.2. General references

***

1. Setting the stage for the recovery of the neglected history of pre-modern industry

1.1. Prologue

Most educational systems, particularly those of Western countries, tell us that industry was born in Europe and that the Industrial Revolution was the mother that delivered industrial mass processes. This paper challenges this view and presents an overview of the industrial and engineering processes which preceded the Industrial Revolution. It briefly examines the vast industry which stretched from China to Spain during the Muslim Civilisation (circa 700-1700 CE); a period sometimes referred to as the “Dark” or “Medieval Ages”.

A brief overview is given of some randomly selected aspects of Muslim industrial production which highlights not only the Islamic antecedents of many processes and products widespread in our modern industrial system, but also how erroneous is the opinion that industrial production was alien to Islamic society.

|

|

Figure 1: Samples of ancient Islamic ceramics in the Museum of Islamic Ceramics in Cairo. Four plates with drawings from Islamic Egypt: (a). Mamluk era, 11th century; (b). Fatimid era, 12th century; (c). Mamluk period, 11th century; (d). Fatimid times, 11th century. (Source). |

Windmills and water-wheels provided power for industrial production. Industrial processes ranged from composite steel to paper making, petroleum, pottery, glass making, textiles, agriculture, ship building, fishing, mineral extraction, metal working, and chemical products. An attempt is made to discuss the rise and fall of this vast industrial experience and reference is made to some lessons to be learnt from that vast human experience.

1.2. The missing history of Islamic industry

A typical university graduate grows up with the notion that industrial production, or manufacturing, is a Western manifestation, dating from the mid to late 18th century. This implies that there was no industry until the English Industrial Revolution of the mid 18th–19th century, followed by that of other countries, for example France, and later Germany, America and Iapan, initiated the birth and development of manufacturing and mass production. This is what is taught to this day in most history and engineering departments in the UK, Europe and US. Also, according to such teaching, and the literature that went with it, the reason why the so-called Third World countries are backward is due to the absence of industrial tradition, and the difficulties they have in initiating what is somehow alien to their societies.

Thirty years after this author passed all his academic degrees secure in such knowledge and started teaching it in reputable Western universities, he came across new learning away from standard books and literature, which surprisingly taught him that [1]:

(i) Industrial production, manufacturing, and mass production for both vast urban populations and for export, relying on machinery powered by wind and water, had existed nearly ten centuries before the 18th century English Industrial Revolution,

(ii) Metals were smelted in huge quantities, in the Muslim world, for local and foreign markets,

(iii) Textiles were produced, from China to Muslim Spain, in ways not so dissimilar from methods we have today,

(iv) Such products were not bartered but sold in exchange for cash, or paid for by cheques honoured and valued across Asia, Africa, and Southern Europe, and,

(v) Capital was invested and reinvested across vast domains according to lines and mechanisms corresponding to our modern methods.

For example, during the Abbasid Caliphate, manufactures of every kind were encouraged and fostered in Iraq and many other lands. Glass and soap were made in the factories of Basra. The paper industry particularly received much impetus. It attracted workers from all over the world, particularly from Egypt. Persia was noted for her gold and embroidery work, which was carried on in all the big cities. High class fabrics including satin, brocade, silk and carpets were manufactured in Islamic domains and were in great demand all over the world. Kufa was famous for its silk and silk handkerchiefs known as kuffiyeh. Khuzistan (ancient Susiana) produced superfine cloth.

The chemical research in Iundishapur, possibly the oldest observatory and college of natural sciences, led to the knowledge of sugar refining which was successfully applied to sugar industry in Khuzistan and later on in Spain. In addition to being famous for its manufacture of Damascus steel swords, Syria was also known for its glass, where, as early as the 9th century, parti-coloured and enamelled glass was produced. The commodities exported during the Abbasid Caliphate were agricultural produce, glass, hardware, silk, textiles, perfumes of all kinds, rose water, saffron, syrup, and oil. In short, every city in the Muslim world had its own particular manufacture in metal, glass, wool, silk or linen.

To sum up this trend of industrial production as accounted for in brief by recent historiographical works, let’s quote the beginning of the only available synthesis on Islamic technology : “Technology is the tool of civilisation, and for Islamic civilisation to have been such a leading force for several centuries, clearly it must have been based on important technological achievements” [2].

|

|

|

Figure 3a-b: Original drawings of the five water raising machines designed and described by al-Jazari in his treatise of mechanics. Respectivey: (a) a machine for raising water from a pool to a higher place by an animal who turns a lever-arm; (b) a machine for raising water from a pool or a well by an animal who rotates it; (c) a machine for raising water by means of an endless chain of pots; (d) a machine for raising water from a pool by means of flumed swape operated by a cranck driven by an animl through gears; (d) pump driven by a water wheelell by an animal who rotates it. Source: Al-Jazari, Kitab ma’rifat al-hiyal al-handasiya, Istanbul, Suleymaniye Library, MS 3472: online version. |

|

1.3. Thriving cities of industry in the Andalus

Under Islam, Spain became very prosperous due to wide ranging industries and large-scale production with revenues from commercial duties exceeding the combined revenues of all the Christian states of Europe. The textile industry for instance in its capital Cordova, had 13,000 looms and Almeria had 4,800 looms [3]. The leather industry was thriving. The art of tanning and embossing leather had been developed to a high degree of perfection and from there it spread to Morocco and North Africa, England and France. High class woollen and silk fabrics were manufactured in Cordova, Malaga, Almeria and other towns. Almeria also produced glassware and brass work [4]. Sericulture (the production of raw silk by raising silkworms) was much developed in Spain. According to the Spanish historian Ibn al-Khaṭīb, Valencia was the home of pottery. The mining industry was fully developed. Iaen and Algrava were famous for their gold and silver mines, Cordova for its iron and lead and Malaga for its rubies. Toledo like Damascus was known throughout the medieval world for its swords. The art of inlaying steel and other metals with gold and silver and decorating them with flower patterns, which was introduced from Damascus, flourished in several European and Spanish centres and left a linguistic heritage in such words as ‘damascene’ ‘damaskeen’, French ‘darnasquiner’ and Latin ‘damschina’.

The Muslims had converted the barren lands of Spain into a garden and developed a vast agricultural industry. Seville alone had several hundreds factories. Besides the textiles and agricultural industries, paper, sugar, gunpowder, porcelain, earthenware, iron, steel and leather industries spread on an extensive scale. The tapestries of Cordova, the woollen stuffs of Murcia, the silk of Granada, Almeria and Seville, the steel and gold work of Toledo and the paper of Salibat were sought all over the world. The glazed tiles and the fine vases still found in the palaces of Alhambra bear testimony to the high quality of porcelain manufacture [5].

|

|

|

Figure 4a-b: Two views of the famous six-cylinder pump described by Taqi al-Din Ibn Ma’ruf: Manuscript view (Taqi al-Din, Al-Turuq al-Saniya fi al-‘ālat al-rūhaniya, Chester Beatty Library in Dublin, MS 5232); and drawings of the virtual reconstruction of the pump. Source: S. Al-Hassani The Machines of Al-Iazari and Taqi Al-Din; S. Al-Hassani and M. A. Al-Lawati, The Six-Cylinder Water Pump of Taqi al-Din: Its Mathematics, Operation and Virtual Design. Click here and here to view animations of the device. |

|

1.4. Omission from History

There are many instances of distorted history, and many writers have given attention to this matter [6]. In this presentation the focus will be on the other means by which history is distorted: that is, the omission of centuries from the educational curriculum and associated history books, especially those aimed at the general public. The focus on this issue is to alert communities to the particular significance of the Muslim civilisation and its historical role in giving birth to much of modern science and technology.

Iohn Glubb very clearly describes this distortion in his History of the Arab People. He tells us:

“Modern oriental studies have proved the falsity of this historical propaganda (the idea of the 16th-17th century Renaissance, and that nothing happened between the 450s (the fall of the Roman Empire) and such Renaissance, although the latter is still widely believed by the general public. Unfortunately, a great part of the educational world still adheres to these ancient taboos and the period of some five or six centuries, which separates the decline of Rome from the Norman invasion of England, is omitted from school curricula and from public examination. As is always the case, this falsification of history for propaganda purposes has iniured us more than anyone else, and has largely been responsible for the many political errors, which our governments have committed in the Middle East in the last sixty years.

The history of `progress’, the rise of man from a primitive state to his modern condition, is a fascinating story. The interest is lost, however, when the continuity is concealed by the omission of periods of several centuries and the presentation of bits and pieces of history, gathered from here and there, in accordance with our own emotional preiudices or our national vanity” [7].

|

|

Figure 5: Two metalworks from classical Islamic times: Incense burner made for Sultan Qala’un (reigned 1294-1340) [Egypt or Syria, 1294-1340; beaten brass, inlaid with gold, silver, and a black compound]; and a large canteen, the only known example of its kind from the Islamic world; it recalls the shape of ceramic pilgrim flasks. Its inlaid silver decoration combines different styles of calligraphy and decorative motifs, such as intricate geometric designs, and lively animal scrolls [Syria, mid-13th century, Brass, silver inlay]. © The Smithsonian Institution, Washington. (Source). |

Of course, Glubb only speaks of those centuries up to 1066 (the time of the Norman invasion of England), but the whole period 450-1492 is in fact passed over as Dark Ages, and is altogether ignored as far as science and civilisation are concerned, termed as ‘a middle age‘, an intermediary period, a uniform bloc, ‘vulgar centuries‘‘ and ‘obscure times‘, as Pernoud says [8]. One challenges any audience to pick ten history books, look into them to find that in at least nine, if not eleven of them (the numerical exaggeration is on purpose to highlight the case), the presentation of scientific achievements iumps from some Greek names of late Antiquity, whomsoever it is, whether Ptolemy, Archimedes, or Galen, straight to Galileo, consequently ignoring scientific and technological events of the period, between 1000 and 1500, as if it were a sterile period. And the same holds with respect to curricula at schools and colleges. Even more disastrously, as the curious audience can gather, from universities, too. How it is that higher learning institutions teach that nothing happened over a thousand years is not iust beyond comprehension, but against academic rules of rigorous questioning. Students, who are trained to think critically, suddenly face a sudden darkness of ten centuries, and then are told things appeared, as if by a miracle, all at once in the Renaissance. It defies logic. Things, as any scientist knows, do not appear by chance. Continuity is basic in the birth and rise of sciences; it is equally so in almost every other field of study [9].

2. Aspects of the industrial production in Islamic civilisation

2.1. Examples: part 1

In this paper the situation pertaining to industry and production is considered. The subiect is huge and unfortunately not much research has been done on it. It is hoped that this paper will trigger debate and interest on a wider scale. During 700-1700 CE, Muslim industrial production ranged from mineral extraction to the production of goods by means of complex processes (the manufacture of paper for instance).

A brief overview here of some randomly selected aspects of Muslim industrial production highlights not iust the Islamic antecedents of many processes and products widespread in our modern industrial system, but also, and above all, how inane is the opinion that industrial production was alien to Islamic society.

Pacey, for instance, notes how mechanical techniques reached a high level of sophistication in the Islamic civilization as well as in China, notably with respect to the application of water wheels to generate power [10].

|

|

Figure 6: Two folio pages (239b – 241b ) of the manuscript Or. 298 at Leiden University Library, which is probably the oldest known Arabic manuscript on paper (dated Dhu al-Qa`da 252 (866 CE). Arabic, paper, 241 ff., upright script (with application of ihmal), bound in a full-leather standard binding. The present volume contains an incomplete copy of Gharib al-Hadith, by Abu `Ubayd al-Qasim b. Sallam al-Baghdadi (d. 223 H/837 CE). (Source). |

2.1.1. Steel

Hammer Pugstall, on the other hand, has noted, how Al-Kindī has left us a classification of sword steel, in which steel is divided into two main classes, namely iron works steel and non iron works steel [11]. Al-Kindī subdivides the iron works steel into two groups: carbon steel and wrought iron. He then states that from the two, a third steel is produced which is called composite steel (murakkab), “which owes its quality to a combination of both male and female properties, hardness and toughness.’ This is apparently laminated steel [12]. Wulf pursues this matter, explaining that the steel industry of Toledo (Spain) was founded by the Muslims, and that by living for centuries in Sicily side by side with the Muslims, the Normans acquired its knowledge, and rather than them transmitting it to the Indonesians, it was Muslim commerce with Iava from the 10th to the 14th century which transmitted the pamor technique [13].

The metalworkers of Islam made bronze, brass, or copper lamps, ewers, bowls, iugs, mugs, cups, basins, and braziers; cast them playfully into the forms of lions, dragons, sphinxes, peacocks, and doves; and sometimes incised them with exquisite patterns, as in a lacelike lamp which can be seen in the Art Institute of Chicago [14].

|

|

Figure 7: Front cover of Arab Seafaring in the Indian Ocean in Ancient and Early Medieval Times by George F. Hourani (Princeton University Press, 1995, Paperback, Expanded Edition). |

The swords of Damascus were of highly tempered steel, adorned with reliefs or inlaid with arabesques, scripts, or other patterns in gold or silver threads [15]. Metallurgy was well developed throughout Spain; Murcia was famous for its iron and brass works, Toledo for its swords, Cordova for shields [16]. “We may without hyperbole rank Islamic books of the ninth to the 18th century as the finest ever issued,” tells Durant. “Which of us can be published in such splendour today?” he asks [17].

Recent research dramatically enriched our views about metalworks and metallurgy in Islamic lands. The investigation of some well known Damascus swords revealed the use of no less than a sort of nanotubes technology, a technology iust discovered at the end of the 20th century. News about this discovery thrived through the media in the last years and articles about this discovery were published by the most serious and respectable science iournals, such as the British world leader in science information, the famous iournal Nature.

It seems indeed, according to outstanding results of scientists, that we can no longer boast about discovering carbon nanotubes in the 21st century, as it now appears that mediaeval Muslim sword-smiths were unknowingly using nanotechnology to develop their tough Damascus swords. Sabres from Damascus date back as far as the tenth century. Strong and sharp, they were forged from Indian steel called wootz.

Peter Paufler of the Technical University of Dresden, Germany, and colleagues studied samples of a 17th-century sword under an electron microscope and found that wootz has a microstructure of nano-metre-sized tubes, iust like carbon nanotubes used in modern technologies for their lightweight strength.

The researchers think that the sophisticated process of forging and annealing the steel formed the nanotubes and the nanowires, and could explain the amazing mechanical properties of the swords. Wootz’s ingredients include iron ores that contain transition-metal impurities. It was thought that these impurities helped cementite wires to form, but it was not clear how. Paufler thinks carbon nanotubes could be the missing piece of the puzzle.

At high temperatures, the impurities in the Indian ores could have catalysed the growth of nanotubes from carbon in the burning wood and leaves used to make the wootz. These tubes could then have filled with cementite to produce the wires in the patterned blades [18].

The steel of Damascus blades had features not found in European steels — a characteristic wavy banding pattern known as damask, extraordinary mechanical properties, and an exceptionally sharp cutting edge. Using high-resolution transmission electron microscopy to examine a sample of Damascus sabre steel from the 17th century, scientists found that it contains carbon nanotubes as well as cementite nanowires. This microstructure may offer insight into the beautiful banding pattern of the ultrahigh-carbon steel created from an ancient recipe that was lost long ago.

|

|

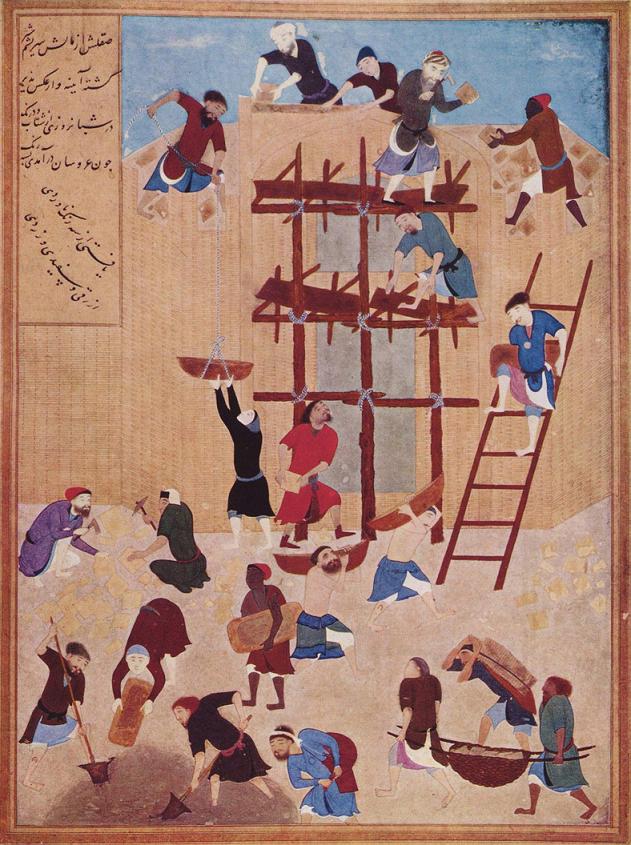

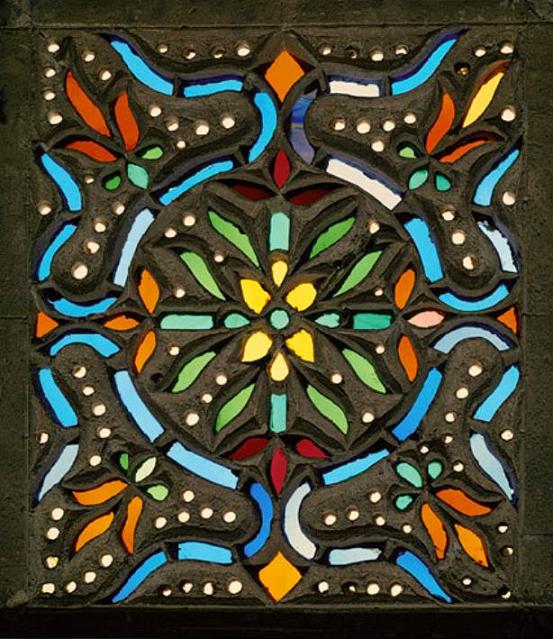

Figure 9: The construction of the Masiid-i Iami in Samarkand, attributed to Behzad (ca.1485,). © Iohn Work Garrett, Library, Iohns Hopkins University, Baltimore, USA. (Source). |

Damascus steel, properly made, is one of the finest cutting tool materials. This quality stems from the use of two or more types of steel, each having its own traits and grades of harden ability, toughness, abrasion resistance, etc. Once combined into multiple alternating layers, heat treated and tempered, the final product exhibits a strength, toughness and sharpness that cannot compare with other single steel blades.

2.1.2. Petroleum

Petroleum was an important product in Islamic economic life long before it attained its present global significance. Crude petroleum (nafṭ) was extracted and distilled extensively; it had both military and domestic uses [19]. Crude oil was usually called black nafṭ and the distillate white nafṭ, even though some of the crude oils were colourless in their natural state. We have a number of descriptions of the distillation process in Arabic writings, as in al-Rāzī’s Book of Secrets. From this we learn that the crude oil was first mixed with white clay or sal ammoniac into “a dough like a thick soup” and then distilled. The light distillates, i.e. the white nafṭ, were used by him to “soften or loosen” some solid substances, such as certain gems and minerals [20].

The oilfields at Baku were developed on a commercial scale by the Muslims at an early date; it is reported that in 885 the Caliph al-Mu’tamid granted the revenues of the nafṭ springs to the inhabitants of Draband. There are several accounts of Baku oil as by al-Mas’ūdī, who, after visiting the wells in 915, wrote that “vessels carrying trade sail to Baku which is the oilfield for white nafṭ and other kinds.” In the 13th century wells were dug at Baku to get down to the source of the nafṭ; it was at this time that Marco Polo reported that a hundred shiploads might be taken from it at one time. Other sources record crude oil production in Iraq where there were seepages on the eastern bank of the Tigris along the road to Mosul. Muslim travellers reported that it was produced on a large scale and was exported. Other reports give information on crude oil production at Sinai in Egypt and Khuzistan in Iran [21].

Besides crude petroleum and its distillates, asphaltes were also abundant. In Iraq, qīr (pitch) and zift (pitch or asphalt) were produced and exported. They became familiar in building construction, especially for baths, and in shipbuilding, while they were also adopted as ingredients in the recipes for many incendiary weapons [22].

2.1.3. Mining and metallurgy

Mineral deposits contributed to the prosperity of the various provinces. Emeralds were exploited in Upper Egypt, turquoises in Ferghana, rubies in Badakhshan, and various stones, varieties of cornelian and onyx in particular, in the Yemen and Spain. The mines of Spain provided gold, silver, tin, copper, iron, lead, alum, sulphur, and mercury. Rubies were also mined at Baia and Malaga in Spain. The cinnabar mines of Almaden in Spain had a workforce of somewhere near a thousand, some cutting the stone down in the pit, others transporting the wood for smelting, making the vessels for melting and refining the mercury, and manning the furnaces [23].

Salt was mined at the Hadhramaut, Ispahan, Armenia and North Africa. “Throughout the greater part of Africa,” writes Leo the African, “salt is entirely of the mined variety, taken from underground workings like those for marble or gypsum.” The polishing of precious stones was done with emery, which was found in Nubia and Ceylon [24]. Egypt and the Sudan both had alum, and certain areas of western Egypt, notably the famous desert of Nitro, had natron, which was used for whitening copper, thread, and linen, and also for curing leather. It was also in demand with dyers, glass-makers and goldsmiths; bakers even mixed it in with their dough and meat-cooks used it as a tenderizer [25].

The pearl industry thrived in the Arabian Sea, and along the Bahrain coast towards the island of Dahlak. Ibn Baṭṭūṭa offers some details of pearl-diving methods:

“The diver attaches a cord to his waist and dives”, he says. “On the bottom, he finds shells embedded in the sand among small stones. He dislodges them with his hand, or a knife brought down with him for the purpose, and collects them in a leather bag slung round his neck. When breath fails, he tugs at the cord, the sign for the man holding it in the boat to pull him up again. Taking off the leather bag, they open up the shells, and cut out with a knife pieces of flesh from inside. On contact with the air these harden and change into pearls, which are then collected, both large and small [26].” In Spain pearls were fished along the Catalonian coasts; whilst coral was gathered along diverse Andalusi shores [27]. There were coral reefs lying off the coasts, of and near Sicily, and Al-Idrīsī gives an account of coral-gathering:

“Coral is a plant which has grown like trees and subsequently petrified deep in the sea between two very high mountains. It is fished with a many-looped hemp tackle; this is moved from high up in the ship; the threads catch the coral branches as they meet them, and the fishermen then draw up the tackle and pick out from it the very considerable quantity of coral [28].”

|

|

Figure 10: Illustration depicting an Islamic ship from a 13th century manuscript of Maqamat al-Hariri (Paris, Bibliothèque Nationale de France, MS Arabe 5847). (Source). |

2.1.4. Chemistry

When one deals with mining and metallurgy, it is necessary to allude to chemistry and chemical industry. In its beginnings, Artz explains, chemistry was mixed with superstition and magic, astrology and other branches of occultism and with fraudulent deception. The basic beliefs of the alchemists were the ideas of Aristotle that all matter consists of the four elements: earth, air, fire, and water, in various combinations, that gold is the “noblest” and “purest” of all metals, silver is next, that the transmutation of one metal into another is possible by an alteration in the admixture of the elements, and, finally, that base metals may be turned into noble ones by means of a precious substance often called the fifth element or quintessence. Much experimenting followed these theories, and the alchemists believed that they could discover an “elixir of life” that would prolong life [29].

Muslim scientists, Ibn Sīnā and Ibn Khaldūn, for instance, attacked such beliefs and practices. Ibn Sīnā, for instance, in The Book of Minerals, denounces the artisans who dye metals in order to give them the outside resemblance of silver and gold. He asserts that fabrication of silver and gold from other metals is “practically impossible and unsustainable from a scientific and philosophical point of view [30].” Ibn Khaldūn, for his part [31], denounces the counterfeiters who apply on top of silver iewellery a thin layer of gold, and make other manipulations of metals. To Ibn Khaldūn, the Divine wisdom wanted gold and silver to be rare metals to guarantee profits and wealth. Their disproportionate growth would make transactions useless and would “run contrary to such wisdom [32].”

Together with Al-Rāzī, they rid the science of its folkloric side to give it its modern outlook. Al-Rāzī, as noted above, in his chemical and medical works observes how he made use of oil lamps (naffaṭa) for gently heating chemicals; the fuel for these was either vegetable oils or petroleum [33]. Al-Rāzī also divided substances into animal, vegetable, and mineral. The mineral substances include mercury, gold, silver, pyrites, glass etc.; vegetable substances were mainly used by physicians. More importantly, Al-Rāzī’s Book of secrets, according to D. R. Hill, foreshadows a laboratory manual, besides dealing with substances, equipment and processes [34]. In such a laboratory, distillation and sublimation was practiced and much of the chemical apparatus in use up to about 1650 was developed [35]. In fact, Al-Rāzī’s laboratory, includes many items still in use today, such as crucible, decensory, cucurbit or retort for distillation (qār) and the head of a still with a delivery tube (ambīq, Latin alembic), and various types of furnace or stove [36].

Before al-Rāzī, Iābir Ibn Hayyān improved methods for evaporation, filtration, sublimation, distillation, and crystallization, described scientifically the two principal operations of chemistry: calcination and reduction, and knew how to prepare chemical substances like sulphide of mercury, arsenious oxide (arsenic trioxide) and lead carbonate [37]. His emphasis on the value of experimentation was passed on to later scientists. “The first essential,” he wrote, “is that you should conduct experiments. For he who does not conduct experiments will never attain to the least degree of mastery. It must be taken as an absolutely rigorous principle that any proposition which is not supported by proofs is nothing more than an assertion which may be true or may be false [38].”

From the laboratory and experimentation spread the production of many industrial items, pharmaceutical, but also used in other industries such as tanning, dyeing, and paper making.

2.1.5. Industrial production of paper

To show the ground breaking impact the Islamic industry of paper had in the universal history, historians of technology don’t hesitate to write:

“The introduction and spread of the paper-making industry in the Near East and Western Mediterranean was one of the main technological achievements of Islamic civilisation. It was a milestone in the history of mankind” [39].

Paper, originally, was brought by the Muslims from China. From an art, the Muslims developed it into a maior industry. The Muslims employed linen as a substitute to the bark of the mulberry, which the Chinese used. Linen rags were disintegrated, saturated with water, and made to ferment. The boiled rags were then cleared of alkaline residue and much of the dirt, then beaten to a pulp by a trip hammer, an improved method of maceration invented by the Muslims [40]. By 950, water power was used in the fibre pounding process in Baghdad [41].

|

|

Figure 11: Four samples of Moorish Cuenca tiles, Portuguese Azuleio from Portugal, inspired from ancient Islamic designs. Handmade Molded Clay Ceramic tile (140mm x 140mm x 10mm) BT 5671 Spanish Moorish tiles Islamic Moroccan tile. (Source). |

In Baghdad many paper mills were built after 793, and from there, the industry spread to various parts of the world. Paper mills which first flourished in Iraq, Syria and Palestine, made their way West. Africa saw its first paper mill built in Egypt around 850. A paper mill was built in Morocco, and from there it reached Spain in 950 [42]. The centre of manufacture was Xativa near Valencia. Paper was first made in Europe by Spanish Moors from the fine flax of Valencia and Murcia. During the Muslim rule, Xativa was the centre of the paper industry in Spain. The adoption of cotton as a material for the production of this article of commerce is said to be due to the practical genius of the artisans of Xativa. At a time when the scribes of Christian Europe were reduced to the necessity of erasing the works of Classical authors to obtain parchment for the preservation of pious homilies and monkish legends, the mills of Xativa were producing great quantities of paper, much of which in texture and finish will compare not unfavourably with that obtained by the most improved process as of modern manufacture [43]. From Spain and Sicily, paper making spread to the Christians of Spain and Italy [44].

This product was indispensable among people of intellectual tastes like the Hispano-Arabs and demand for it was enormous [45]. By the year 1000, paper was in general use throughout the Islamic world, not only for books, but also as wrapping material and napkins [46]. The paper mills constructed in Damascus were the maior sources of supply to Europe. As production increased, the product became cheaper. more available, and of better quality. Cotton paper, sold as charta Damascena, was previously made in Damascus.

Of course, paper seems so ordinary today, but its use is fundamental to modern civilisation. By making use of the new material, paper, manufacturing it on a large scale, and devising new methods for its production, the Muslims, in the words of Pedersen “accomplished a feat of crucial significance not only to the history of the Islamic book but also to the whole world of books [47].” The other decisive impact of Muslim manufacture of paper was, obviously, and directly to bring about the invention of printing [48].

2.2.1. Pottery

Extensive use was made of pottery, for cooking, lighting and washing. In the bazaar in Cairo, according to a Persian writer of the 11th century, grocers, druggists and ironmongers provided the glasses, the faience vessels and the paper to hold or wrap what they sold. “Daily”, Al-Maqrīzī (a 13th-century Muslim historian), tells, “there is thrown on to the refuse heaps and waste piles –waste to a value of some thousand dinars– the discarded remains of the red-baked clay in which milk-sellers put their milk, cheese-sellers their cheese, and the poor the rations they eat on the spot in the cook-shops [49].”

Different uses were made of pottery in Muslim Spain. Because of the widespread diffusion of the water lifting machine, the noria, its pot, the qādūs, became the universal unglazed pot and it must have been the mainstay of the rural pottery industry until it was replaced by tin fairly recently. The most popular pot, with a middle waist and a knob on the bottom to facilitate the lashing of the pot to the noria rope, is related to Syrian pots. Also common were flat-bottomed vessels with a hole in the bottom, which historian of technology Glick explains had a variety of purposes: as a casserole, according to an Andalusi-Magribi cookbook of the 13th century; as a flower pot, according to the botanist Ibn Baṣṣāl; and, in irrigated areas where delivery of water was timed, as an outflow clepsydra (hanging water clock) through the vent of which water issued in a determinate time [50].

In the East, pottery centres developed at Baghdad, Samarra and many other towns. In the 9th century the potters of Samarra and Baghdad distinguished themselves by making, perhaps inventing, lustre pottery. The decoration was painted in a metallic oxide upon the glazed coating of the clay, and the vessel was then submitted to a smoky and subdued second firing, which reduced the pigment to a thin layer of metal, and gave the glaze an iridescent glow [51]. Exquisite monochromes were produced in this manner, and still more exquisite polychromes in gold, green, brown, yellow, and red, in a hundred almost fluid tints [52]. The lustre technique was applied also to the ancient art of decorative tiles; the rich colours of these squares, and their harmonious combinations, gave unique splendour to the portals or mihrabs of hundreds of mosques, and to many palace walls [53].

|

|

Figure 12: Goblet, 9th century, probably from Egypt, transparent pale greenish blue glass, blown from two gathers and scratch-engraved (height 11.9 cm, diameter 9.2 cm). Inscription (in kufic script): “Blessings from Allah to the owner of the goblet. Drink!”. Formulas including good wishes were commonly found on eating and drinking vessels in both pottery and glass. (Source). |

2.2.2. Ceramics

Ceramics of finer quality were also produced, and firing workshops in general were very active throughout almost the entire Muslim world, the potteries of the Muslim east rivalling the faience workshops of Tunis and Cordova. The glazed faience tiles of Malaga, known as azuleios, are still famous. The diffusion of glazed wares into Spain from the East can be traced with great precision, owing to the chemical specificity of the glaze recipes [54]. Thus we know that the blue glaze of cobalt oxide was introduced from the East to Málaga during the Taifa period, from where it spread to Murcia and then to Christian Spain, to Valencia (at the beginning of the 14th century) and Barcelona (at the end of the century) [55].

This following description of a modern potter’s wheel is probably applicable to all those of the Middle Ages:

“The potter’s wheel consists of a sloping tray over which is a wooden axis supporting a further piece of wood in the shape of a disc, the whole resting on a cross-bar. The lower wheel is turned by the craftsman with his foot, an action requiring no great expenditure of energy; in consequence of its inclination, the tray is carried round and over by its own weight [56].”

An 11th century Persian traveller conveys an idea of the quality of Egyptian faience at the time: “Egypt produces faience of every kind; so fine and transparent that a hand placed against the outside of a vase may be seen from inside. Bowls, cups, plates, and other utensils are made. They are decorated with colours that change with the position of the vessel [57].”

Historians today note with surprise the wide variety of eastern ceramics and the techniques employed in their manufacture. So rich was the Islamic industry in this field that it easily impacted on the West [58].

The history of ceramic production in the medieval Muslim world, from the period of the Umayyads in the 7th century to the Ottomans and Safavids in the 17th century, attests to the superior creativity and experimentation of Muslim potters, demonstrated through their innovations in shape and design, clay recipes, glazes, and techniques of decoration.

As shown by the recent studies, glazed and painted ceramics were highly sought commodities in urban as well as courtly contexts. Potters of the Islamic lands experimented with specially made tin and alkaline glazes that fired to an opaque creamy-white finish. Around the 12th century, they also developed alternative clay recipes by adding large quantities of crushed quartz to produce a hard, white ceramic body, known as “fritware” or “stone-paste”. It was largely used in the Islamic world for different types of fine ceramics from the 12th century onward [59].

2.2.3. Glass

Throughout the Islamic world, glass was either cut from crystal or blown into moulds. Aleppo in Syria was mentioned as a glassmaking and decorating centre by the geographers Yaqūt Al-Hamawī (d. 1229) and Al-Qazwīnī (d. 1283). Damascus, too, was described as a glassmaking centre by Ibn Baṭṭūṭa (d. 1377) and Niccolo of Poggibonsi, who travelled in the Holy Land in 1345-46 [60]. Excavations at Iabal, an Umayyad palace in the Syrian countryside, revealed a quantity of domestic glassware; excavations at Hama yielded a wide range of later material, mostly of the period between 1100 and 1400 [61]. A large amount of glass has been recovered from excavations in Ierusalem where, according to the geographer al-Muqaddasī, lamps were made in the 10th century [62]. Syrian glasses were particularly prized the world over. Even such fragile obiects as Syrian enamelled glass of the 13th century have been found in Sweden [63].

|

|

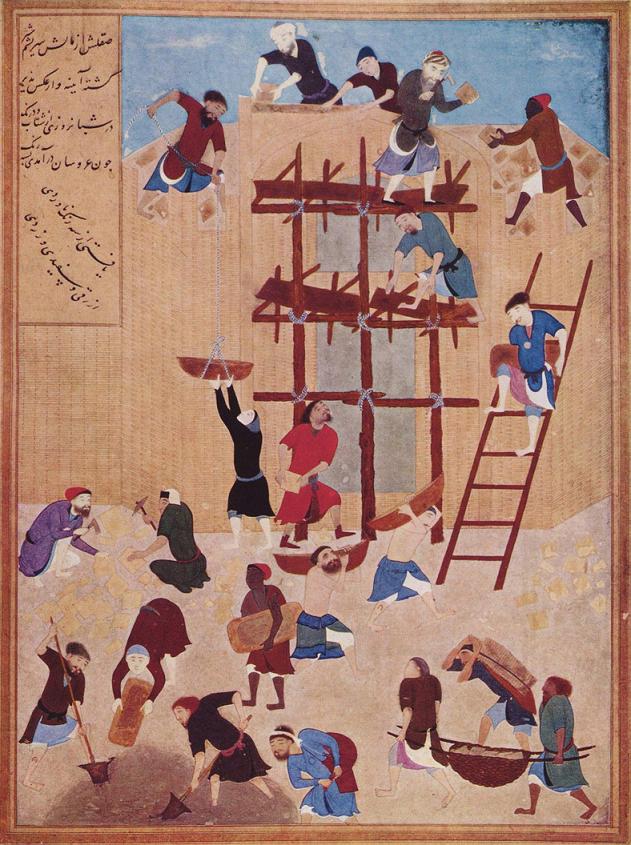

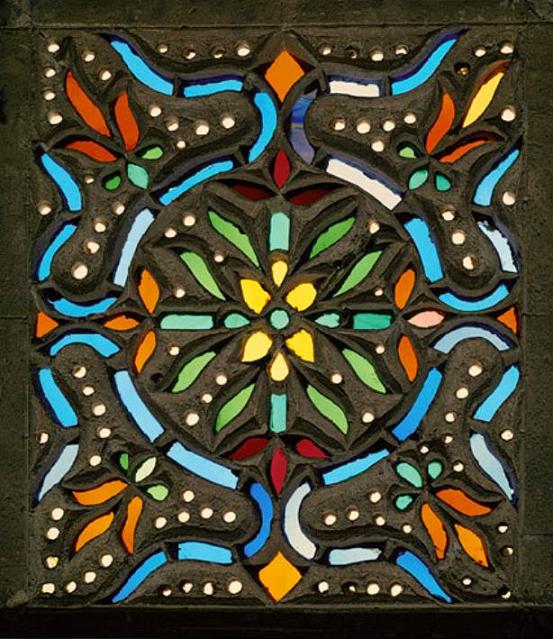

Figure 13: Window in stained glass, 17th century, Egypt or Syria (38.7 x 48.3 cm). A window such as this with brightly colored panes in blue, orange, green, and red might have been found in a room of an aristocratic home in the Islamic world. Tinted glass was favored because it filtered the light, but it also complemented the multihued furnishings of the room. (Source). |

Islamic glass has also been found in a few medieval European sites, the discovery of such glass obiects in Sweden, southern Russia, and even in China, indicating that distance did not always prevent them being transported [64]. Egypt was also famed for glassmaking, and continued to produce vessels of all qualities in the Islamic period [65]. Excavations at Al-Fustat (the forerunner of Cairo, founded in 969) have provided an immense quantity of glass, ranging in date from the 8th century to the later Middle Ages; the sheer abundance of such finds presumes that Al-Fustat was a centre of production. Among the earliest datable obiects (the earliest datable glass weight was made in 708) are coin-like weights, stamped with the names of rulers or government officials [66]. They came in a variety of colours, among which are dark green, light green and turquoise, white and purple. Some of the most sophisticated Egyptian glass vessels were decorated with lustre [67]. This shiny, sometimes metallic effect was achieved by painting copper or silver oxide on the surface of the obiect, which was then fired at a temperature of about 600°C (1112°F) in reducing conditions. The same technique, as already noted, was used in the decoration of earthenware, not only in Egypt but also in Iraq and Iran. Until recently, controversy raged over the origin of lustre painting, but the problem appears to have been solved by the discovery at Al-Fustat, of a glass cup of local type, inscribed with the name of ‘Abd al-?amad, governor of Egypt in 771-772; Egyptian glass painters were therefore using lustre some time before its appearance in Iraq [68].

In Al-Andalus, glass vessels were blown in Almería, Málaga, and Murcia in imitation of eastern wares, such as the irakes –glass goblets– so favoured on the noble tables of 10th-century León. The technique of cutting crystal was said to have been introduced by ‘Abbās ibn Firnās (d. 887), scholar and inventor in the courts of ‘Abd al-Raḥmān II and Muḥammad I [69]. It is worth pointing here to the genius of Ibn Firnās, who was not only able to decipher the most complex writing, but also made attempts at flying by building artificial wings [70]. In relation to glass, he was familiar with the scientific properties of glass, and contributed to the early experiment with lenses and the idea of magnifying script by their use [71]. He also lent his skills to the glass making furnaces of Cordova, and made a representation of the sky in glass, which he was able at will to make clear or cloudy, with lightning and the noise of thunder at the press of a finger [72].

2.2.4. Textile

Textiles were exceptionally important in the art and economy of Islam from the earliest times. Their role, Whelan notes, has been compared to that of steel in the modern industrial economy, and it has been estimated that in the Middle Ages textile manufacture and trade may have occupied a maiority of the working population [73]. Some sources claim that there were 3,000 weavers in Cordova alone [74]. Cordova made “Cordovan” leather for the “cordwainers” (cordobanes) of Europe, and also carpets, cushions, silk curtains, shawls, and divans, which found eager buyers everywhere [75]. In al-Andalus, the production of eastern-style cloth was concentrated in the towns of Málaga and Almería, which, as ports, were the first to receive the new techniques or styles [76]. Almería’s role in this process was particularly important in the 12th century. In the industry of ṭirāz and of silk there were eight hundred workshops and one thousand for excellent tunics and brocade, and as many more for ciclaton [77]. This pre-eminence can be partly explained, Whelan notes, again, by the variety of uses to which textiles were put in the Near East and along the Mediterranean shores. Aside from clothing, they also constituted the bulk of household furnishings; nomad women weaving tent bands, saddlebags, cradles, and other appurtenances of their mobile lives, but even in the urban centres and in the palaces furnishings consisted mainly of carpets, covers, curtains, and hangings of various kinds. Instead of chairs, people sat on cushions and leaned against bolsters, all covered with cloth whose quality and richness reflected their owners’ means [78]. Textiles also played an important political role. As well as lavish diplomatic gifts, it was customary to reward high officials and other favourites, both at regular intervals and on special occasions, with “robes of honour” (khil?a’), turbans, and other garments woven in the rulers’ own establishments. It was also the Caliphs’ prerogative — and after 1250 that of the Mamluk Sultans— to provide each year the new kiswa, the richly ornamented cloth that veiled the Kaaba at Mecca [79].

The full range of textile fibres was available in the Islamic world. Wool and linen were produced in quantity from Iran to Spain, and additional supplies of the latter were imported. Cotton, native to India was probably first produced on a large scale in the Mediterranean after the Muslim advance; especially in Syria and Palestine [80]. The Muslims eventually took both crop and industry to Western Europe [81].

In addition to the various textile expressions derived from Arabic, some towns and cities were internationally recognised for their product. Shiraz was famous for its woollen cloths, Baghdad for its baldachin hangings and tabby silks; Khuzistan for fabrics of camel’s or goat’s hair; Khurasan for its sofa covers, Tyre for its carpets, Boukhara for its prayer rugs, Herat for its gold brocades [82]. However, no examples of these products from this period have survived the wear and tear of time.

|

|

Figure 14: Two views of antique Damascus swords. Research on Damascus steel revealed the use of a proto concept of nanotechnology. |

In the embellishment of Islamic life all the arts mingled like the interlaces of a decorative theme. So the patterns of illumination and calligraphy were woven into textiles, burned into pottery, and mounted on portals and mihrabs. “If medieval civilization made little distinction between artist and artisan,” Durant notes, again, “it was not to belittle the artist but to ennoble the artisan; the goal of every industry was to become an art. The weaver, like the potter, made un-distinguished products for ephemeral use; but sometimes his skill and patience found expression, his dream found form, in robes or hangings, rugs or coverings, embroideries or brocades, woven for many lifetimes, designed with the finesse of a miniature, and dyed in the gorgeous colours so favoured of the East [83].”‘

2.2.5. Ship building

The Muslim world was dotted with shipyards making ships and vessels of various sizes and types. In Muslim Spain, for example, the economy of the ninth and tenth centuries stimulated alongside the construction of war ships the development of a navy designed for sailing along the coasts of the kingdom, and to more distant places, whether to the Baleiric islands, the North African coast or Egypt [84]. In addition to Almeira, there were many Andalusian ports which constituted more or less important bases for warships, and also were equipped with ship building yards, called either Dār al-insha’, or Dār ṣinā’at al-marākib (or simply Dār al-ṣinā’a), from which the modern word arsenal originated. Amongst them, Alcacer do Sal, Silves, Seville, Algeciras, Malaga, Alicante, Denia. At Tortosa, near Catalonia, an inscription shows that a shipyard was established under the orders of ‘Abd al-Raḥmānn III in 945, and it owed its renown to the quality of the wood of its surrounding forests [85].

During the medieval period, shipbuilding was a maior industry. It was directed towards the construction of merchant vessels and for building and fitting out warships. The main shipyards were the property of the state, but there existed private yards on the banks of the great rivers and the shores of the Gulf and the Red Sea, belonging to merchants and to private persons who use them for trade and travel. The shipbuilding industry was engaged in building many varieties of ships, from small oared skiffs to huge vessels aimed at performing long travels, of over 1000 tonnes capacity and warships capable of carrying 1500 men [86].

It is worth noting here that the world famous Chinese Admiral, Zeng He who built a fleet of gigantic iunk ships (each the size of a football playground) chartering the great oceans of the world, was a Muslim who performed pilgrimage to Makka whilst quite young, some say must have influenced his vision of the world outside China [87].

The impact of Muslim ship construction is not iust perceptible through the large number of words of Arabic origin to be found in modern Western languages, the best known being Arsenal and Admiral (originally Amīr al-baḥr), but in the impact Muslim ship construction made on the West [88],

2.2.6. Agriculture and farming

A short word here courtesy of Scott on how the Muslims impinged on their neighbours in southern Europe in some of the basic aspects of agro-industries and crafts:

“The Moorish principality of Narbonne was subiect to the Western Emirate only forty years; yet, during that short period, the impressions produced by Moorish occupancy were so deeply stamped upon the mental and physical characteristics of the population that no subsequent revolutions have ever been able to entirely efface them. The practical genius of the Arab, which considered utility as the first and most valuable of all the obiects of civilization, was again exhibited in the improvements applied to all the arts and avocations of life, which sprang up in the track of his victorious armies. The Oriental principles of agriculture, with its painstaking tillage of the soil, its perfect irrigating system, its introduction of foreign plants, were applied with wonderful success to the delightful region watered by the Rhone and the Garonne. The bark of the cork-tree, still one of the greatest sources of wealth to Catalonia and Provence, was then first made known to Europe. The boundless evergreen forests on the slopes of the Pyrenees were utilized for the manufacture of pitch and rosin. In every district, the breed of horses was improved by crosses with the best blood of Arabia. Innumerable articles of luxury preserved in museums and private collections –beautiful obiects of silver, ivory, and crystal, damascened armour, and silken robes– attest the variety and excellence of the Moorish manufactures [89].’

|

|

Figure 15: Two Islamic knifes (khaniar) made of Damascus steel, wih a view on the detail of their surface. So-called Damascus steel swords were known from around the seventh century onward and dominated warfare for centuries as a result of their good toughness in combination with their outstanding cutting ability. The name derives from the fact that these swords were first encountered by Europeans in Damascus. Damascus steel swords are still regarded in this manner as evidenced by continuing efforts up to the present time to determine the methodology used to produce the swords. (Source). |

3. Science, management and industrial growth

Ibn al-Haytham revolutionised optics and consultation of any of his works, Kitāb al-Manāẓir in particular, will surprise people how many industrial items (the camera, telescopes, glasses etc.) we owe to his pioneering work [90]. It was, indeed, Ibn al-Haytham, who completely dismissed the Greek theories of Euclid and Ptolemy, that the eye sends out visual rays to the obiect being viewed. Instead he demonstrated that the form of the perceived obiect passes into the eye and is transmuted by its lens. He found the relationship between the positions of a source of light and its image formed by a lens. He discussed the propagation of light and colours, optical illusions, and reflection of light, and gave methods for measuring the angles of incidence and refraction [91]. Ibn al-Haytham’s experiments, recreated in modern history of science, are a precursor of all that has to do with optical technology and industry [92]. Muslim physics also included the determination of the specific gravity of certain metals and precious stones, and work on meteorology, on tides, and on such problems of applied mechanics as windmills and water-wheels (which the Muslims were the first to develop), balances, wells, water clocks, agricultural methods, irrigation, canal and road building, the preparation of iron and steel, methods of working metals, constructing scientific instruments, paper-making, leather work, and silk and cotton cloth manufacture.

For greater details on this matter, Pacey offers a good variety of examples, most particularly on how industrial techniques circulated between civilisations and down the ages [93]. Singer, though, in each of his works, especially the lesser known ones, highlights the role of the East, the Muslim world, and also China and India, who were centuries ahead of the rest in promoting industrial technologies [94].

Muslim management and administrative skills can be seen in Norman Sicily as Scott explains. In the departments of government, finance, legislation, the regulation of commerce, in the protection and encouragement of agriculture, in the maintenance of order, Sicily offered the best example in Europe, with the exception of Muslim Spain [95]. Its coinage was one of the purest, the most convenient, the most beautifully executed that had ever been put in circulation by any government, and the regulations of the kingdom concerning the rural economy of its people were minute and specific, even paternal, in their character [96]. The supervision exercised by government officials over all occupations was most precise. Weights and measures, for instance, were prescribed by law, and any departure from honest dealing in this respect was visited with the severest penalties. Officers were appointed in every town for the detection of false weights and the sale of spurious merchandise. The laws of hygiene were understood and enforced with a degree of intelligence unknown to many European communities until recently in modern times, and unwholesome provisions could not be exposed for sale in the markets [97].

All this reminds of the Muslim institution of ḥisba, operated by the muḥtassib [98]. The muḥtasib‘s primary domain was the market, where he was charged with supervision of all trades and crafts. He ensured that all goods were properly made, that foodstuffs were well prepared and wholesome, and that services were performed correctly. Most particularly, he guarded against misrepresentations, frauds, and deceptions of all kinds. Working conditions, sanitation, and public safety also came under his authority. He could not fix prices, but could take action against hoarding or price gouging. The muḥtasib‘s responsibilities extended elsewhere. He supervised mosques, schools, baths, and workshops, made sure that the city walls were in good repair; and kept the streets clear of obstacles and encroachments. Realtors and builders were answerable to him for their transactions and constructions. He could prevent ship-owners from overloading their boats or setting out in bad weather and could order that overburdened beasts be relieved of part of their loads [99].

To execute these tasks, the muḥtasib often employed assistants, who were knowledgeable in specific fields; at times he also had a body of troops at his command, which made him a force to be reckoned with in times of instability. His powers were considered to be subordinate to those of the Cadi (iudge); but while the latter could only pass iudgment on matters formally presented to him, the muḥtasib intervened on his own initiative and made decisions on the spot. He could have offenders beaten, flogged, or hauled through the streets in disgrace; and it was within his powers to confiscate or destroy false weights and measures, defective merchandise, and forbidden items such as wine [100].

This area of study may be expanded by looking at the whole system of trade, the diverse financial mechanisms, the role of the cheque and commenda, etc. However, this would mean opening a whole new subiect, which is beyond the scope of this article. It would be important, however, to investigate where all such wealth and activity went. What made the Muslims, the initiators of industrial activity on the widest scale retreat into the state of impotence, which they suffer from today? Such questions remain to be answered.

|

|

Figure 16: Analysis of the nanotube structure of Damascus steel. The swords forged in Damascushad a surface pattern of moiré ripples, which resemble turbulent water, with a wavy pattern on its surface which looks like wood grain. Details: (a). A Damascus sword; (b). the wavy pattern in the sword; (c-d). the nanowire structure of the steel in the blade. (Source: C. Srinivasan, Damascus Sword – An Ancient Product of Nanotechnology). |

4. References and bibliography

4.1. Articles published on www.MuslimHeritage.com

4.2. General references

Footnotes

[1] See literature as follows: M. Lombard, The Golden Age of Islam; translated by I. Spencer; Amsterdam: North-Holland publishers, 1975, p. 239; S.D. Goitein, A Mediterranean Society, 5 vols., Berkeley: University of California Press, 1967-1990; vol. 1, paperback edition, 2000; and various articles on mechanics, engineering, and industry at www.MuslimHeritage.com.

[2] A. Y. al-Hassan, and D. R. Hill, Islamic Technology. An Illustrated History. Paris/Cambridge: UNESCO/ Cambridge University Press, 1986, p. xiii.

[3] P. K. Hitti, History of the Arabs, MacMillan, London, 1970.

[4] Al-Maqarrī, Nafh Al-Tīb: translated by P. De Gayangos: The History of the Mohammedan Dynasties in Spain (extracted from Nafh Al-Tīb by al-Maqqarī), 2 vols., London: The Oriental Translation Fund, 1840-43.

[5] For an overview on the technology of al-Andalus, see D. R. Hill, “Andalusian Technology”, in Studies in Medieval Islamic Technology: From Philo to al-Iazarī-From Alexandria to Diyār Bakr. Edited by David A. King. (Variorum Collected Studies Series). Aldershot, Eng. /Brookfield, Vt.: Ashgate, 1998, XVIII.

[6] For instance, D.H. Fischer, Historians’ Fallacies, London: Routledge & Kegan Paul, 1971; I. Fontana, The Distorted Past, Blackwell, 1995; G. Fisher, The Barbary Legend, Oxford, 1957; P. Geyl: Use and Abuse of History, Yale University Press, 1955.

[7] Iohn Glubb, A Short History of the Arab Peoples; Hodder and Stoughton, 1969, pp. 289-90.

[8] Regine Pernoud: Pour en finir avec le Moyen Age, Paris: Editions du Seuil, 1977, p. 17.

[9] See also A. Y. al-Hassan’s and D. R. Hill’s enumeration of the factors behind the historians’ reluctrance to admit Islamic achievements in technology and industry in Islamic Technology. An Illustrated History, op. cit., pp. 279-281.

[10] A. Pacey, Technology in World Civilization, Cambridge, Mass.: MIT Press, 1991, preface, p. 26.

[11] I. Hammer-Purgstall, “Sur les lames des Orientaux”, Iournal Asiatique, III – IV (1854), pp. 66 ff.

[12] H.E. Wulf, “Notes on Damascene Steel and Pamor”, Technology and Culture; vol 6, pp. 627-629; p. 628.

[13] Ibid, p. 629.

[14] W. Durant, The Age of Faith, New York: Simon and Shuster, 1950, p. 274.

[15] Ibid, pp. 274-5.

[16] Ibid, p. 298.

[17] Ibid, p. 275. For more details on the Islamic contribution to the industry of iron and steel, see A. Y. al-Hassan and D. R. Hill, Islamic Technology. An Illustrated History, op. cit., pp. 251-260.

[18] A. A. Levin, D. C. Meyer, M. Reibold, W. Kochmann, N. Pätzke, and P. Paufler, “Microstructure of a genuine Damascus sabre”, Cryst. Res. Technol. 40, No. 9, 905 – 916 (2005) [online version: Microstructure of a genuine Damascus sabre]; M. Reibold et al., “Materials: Carbon nanotubes in an ancient Damascus sabre”, Nature 444, 286 (16 November 2006); Iohn Verhoeven and Alfred Pendray, “The Mystery of the Damascus Sword”, Muse, Volume 2, Number 2, pp. 35-43, April 1998 [republished online: The Mystery of the Damascus Sword]; I.D. Verhoeven, A.H. Pendray, and W.E. Dauksch, “The Key Role of Impurities in Ancient Damascus Steel Blades”, IOM, Iournal of Minerals, Metals, and Materials 50 (9) (1998), pp. 58-64 [for an online version click here]; Pätzke et al., Nanostructured Ancient Damascus Blades (abstract). See also for more information: Damascus Steel & Silver Inlay; [Wikipedia], Damascus steel (retrieved 5 Iuly 2009); Damascene Technique in Metal Working; Damascus steel’s lost secret found; Mason Inman, Legendary Swords’ Sharpness, Strength From Nanotubes, Study Says, National Geographic News, 16 November 2006.

[19] D. R. Hill, Islamic Science and Engineering, Edinburgh University Press, 1993, pp. 87-88.

[20] Ibidem.

[21] Ibidem.

[22] Ibidem. More details are in A. Y. al-Hassan and D. R. Hill, Islamic Technology. An Illustrated History, op. cit., pp. 145-146.

[23] G. Wiet et al., History of Mankind, vol. 3: The Great Medieval Civilisations, translated from the French; UNESCO/George Allen and Unwin Ltd, 1975, p. 334; W. Durant, The Age of Faith, op. cit., p. 298.

[24] Ibidem.

[25] See A. Y. al-Hassan and D. R. Hill, Islamic Technology. An Illustrated History, op. cit., pp. 233-243, where the two authors quote a profusion of extracts from original manuscripts on the mining and metallurgy industries and techniques in Muslim lands; the ioint article by al-Hassan and Hill, “Mining Technology”, which constitutes section 2 of the entry on “Ma’ādin”, in Encyclopaedia of Islam, New Edtion, Leiden: E. I. Brill, 1986, vol. 5, pp. 967-973; and Michael G. Morony, “Mining: Sources of Gold and Silver According to al-Hamdānī”, in Michael G. Morony, Production and the Exploitation of Resources (Series: The Formation of the Classical Islamic World). Aldershot, Hampshire: Ashgate Variorum, 2003.

[26] Ibidem.

[27] W. Durant:, The Age of Faith, op. cit., p. 298.

[28] G.Wiet et al., History, op. cit., p. 334.

[29] F.B. Artz: The Mind: The Mind of the Middle Ages; Third edition revised. Chicago/London: The University of Chicago Press, 1980, p. 165.

[30] Georges Anawati: “Arabic Alchemy”, in Encyclopedia of the History of Arabic Science, 3 vols. Edited by Roshdi Rashed et al.; Routledge, London and New York: 1996, pp. 853-885; p. 877. One has to be careful of Anawati’s article, though. Whilst Ibn Sīnā and Ibn Khaldūn never attacked the science of chemistry, iust the crooked versions of it, Anawati, like others, eagerly generalises and accuses them of attacking the science itself. In neither the work of Ibn Khaldūn or of Ibn Sīnā, who was himself a chemist, is there a single instance of an attack on the science itself.

[31] For greater detail on Ibn Khaldūn’s view of alchemy, see: Hamed A. Ead: “Alchemy in Ibn Khaldun’s Muqaddimah” at http://www.levity.com/alchemy/islam20.html.

[32] G. Anawati, “Arabic Alchemy”, op. cit., p. 881.

[33] D.R. Hill: Islamic Science, op. cit.; p. 87.

[34] D.R. Hill, Islamic Science and Engineering, op. cit., p. 83.

[35] F.B. Artz, The Mind, op. cit., pp. 165-66.

[36] C.I. Singer et al., History of Technology, 5 vols; Oxford: Clarendon Press; see vol 2 (1956), particularly on pp. 753-777; D.R. Hill, Islamic Science and Engineering, op. cit., p. 83; C. Singer, A Short History of Scientific Ideas to 1900, Oxford University Press, 1959, p. 185.

[37] F.B. Artz, The Mind, op. cit., pp. 165-66.

[38] E.I. Holmyard, The Great Chemists, London, 1929.

[39] A. Y. al-Hassan and D. R. Hill, Islamic Technology. An Illustrated History, op. cit., p. 190.

[40] D. Hunter, Papermaking: the History and Technique of an Ancient Craft, London: Pleiades Books, 1943; 2nd edit. 1947, p. 139.

[41] F. and I. Gies, Cathedral, Forge, and Waterwheel: Technology and Invention in the Middle Ages. Harper Perennial, 1995, p. 97; I. Mokyr, The Lever of Riches: Technological Creativity and Economic Progress, Oxford, 1990, p. 41.

[42] D. Hunter, Papermaking, op. cit., p. 470.

[43] S.P. Scott: History of the Moorish Empire in Europe, 3 vols., Philadelphia and London: I.B. Lippincott Company, 1904, vol. 2, p. 387.

[44] T.K. Derry and T.I. Williams, A Short History of Technology; Oxford Clarendon Press, 1960, p. 232; W. M.Watt, “L’Influence de l’Islam sur l’Europe médiévale”, Revue des Etudes Islamiques, vol 40 (1974), p. 36.

[45] S.P. Scott, History, op. cit., vol 2, p. 387.

[46] F. and I. Gies, Cathedral, op. cit, p. 97; I. Mokyr, The Lever of Riches, op. cit.,p. 41.

[47] I. Pedersen, The Arabic Book, op. cit., p. 59.

[48] T.K. Derry and T.I. Williams, A Short History of Technology, op. cit., p. 231. For more accounts on the growth of the industry of paper in Islam, see: I. Pedersen, The Arabic Book, translated by Geoffrey French; Princeton, NI: Princeton University Press, 1984; M.M. Sibai, Mosque Libraries: An Historical Study, London and New York: Mansell Publishing Limited, 1987, and Ionathan Bloom, Paper Before Print. The History and Impact of Paper in the Islamic World. New Haven: Yale University Press, 2001.

[49] Quoted in G. Wiet et al., History of Mankind, vol. 3: The Great Medieval Civilisations, op. cit., p. 335.

[50] T. Glick, Islamic and Christian Spain in the Early Middle Ages. Princeton, NI: Princeton University Press, 1979, p. 239.

[51] W. Durant, The Age of Faith, op. cit., p. 275.

[52] Ibid.

[53] See Venetia Porte, Islamic Tiles. New York: Interlink Books, revised edition, 2004. Earlier editions include British Museum Press, London, 1st edition 1995, 2nd 1999; Interlink Books, New York, 1995.

[54] T. Glick, Islamic and Christian Spain, op. cit., p.239.

[55] Ibid.

[56] G. Wiet et al., History, op. cit., p. 335.

[57] Ibidem.

[58] It is worth pointing out here that for anyone interested in how all these industries and crafts were passed onto the West, the briefest and most informative outline is provided by S. Feber, Islam and the Medieval West. A Loan Exhibition at the University Art Gallery, State University of New York at Binghamton, April 6-May 4, 1975. For ceramics, for instance, the article by R. Schnyder is very enlightening: R. Schnyder, “Islamic Ceramics: A Source of Inspiration for Medieval European Art”, in S. Ferber ibidem.

[59] Fahmida Suleman, “Ceramics”, Medieval Islamic Civilization, An Encyclopaedia, ed. Iosef W. Meri, New York-London: Routledge, 2006, vol. 1, pp. 143-144. See also the section on “ceramics” in A. Y. al-Hassan and D. R. Hill, Islamic Technology. An Illustrated History, op. cit., pp. 160-170 and Iames W. Allan, Islamic Ceramics. Oxford: Ashmolean Museum, 1991.

[60] D. Whitehouse, “Glass”, in Dictionary of the Middle Ages, I.R. Strayer (editor in chief), New York: Charles Scribner’s Sons, 1980 fwd., vol 5, pp. 545-58; p. 547.

[61] Ibid, p. 546.

[62] Ibidem.

[63] R. Ettinghausen, “Muslim Decorative Arts and Painting their nature and impact on the Medieval West”, in S. Feber (ed.), Islam and the Medieval West, op. cit.

[64] Ibid.

[65] D. Whitehouse, Glass, op. cit., p. 546.

[66] Ibid, p. 546.

[67] On decoration techniques of glass, see A. Y. al-Hassan and D. R. Hill, Islamic Technology. An Illustrated History, op. cit., pp. 156-160.

[68] D. Whitehouse, Glass, op. cit., p. 546.

[69] T. Glick, Islamic and Christian Spain, op. cit., p. 241.

[70] A. Diebbar: Une Histoire de la Science Arabe, Paris: Le Seuil, 2001, p. 274; S. and N. Ronart, Concise Encyclopaedia of Arabic Civilization. The Arab West, Amsterdam, 1966, p. 142.

[71] A. Diebbar, Une Histoire, op. cit., 272-274.

[72] Levi Provençal, in G. Wiet et al., History, op. cit., p. 336.

[73] E. Whelan, “Textiles”, in Dictionary of the Middle Ages, vol. 11, p. 715.

[74] W. Durant, The Age of Faith, op. cit., p. 298.

[75] Ibidem.

[76] T. Glick, Islamic and Christian Spain, op. cit., p. 243.

[77] Ibidem.

[78] E. Whelan, Textiles, op. cit., p.716.

[79] Ibidem.

[80] E. Whelan, Textiles, op. cit., p. 716.

[81] W. Heyd, Histoire du Commerce du Levant au Moyen Age, Amsterdam: A.M. Hakkert Editor, 1967.

[82] W. Durant, The Age, op. cit., p. 278.

[83] Ibidem.

[84] E. Levi Provencal: Histoire de l’Espagne Musulmane, vol 3, Paris, Maisonneuve, 1953, pp. 154, 321-22; M. Lombard, The Golden Age of Islam, transl. I. Spencer; North Holland publishers, 1975, p. 192.

[85] E. Levi Provençal, Histoire de l’Espagne, op. cit.; M. Lombard, The Golden Age of Islam.

[86] On shipbuilding and navigation in the history of Islamic countries, see A. Y. al-Hassan and D. R. Hill, Islamic Technology. An Illustrated History, op. cit., pp. 123-131; and H. Homsi: “Navigation and Ship-building , in A. Y. al-Hassan, Y. Iskandar, A. Zaki, and A. Maqbul, (eds.), The Different Aspects of Islamic Culture. Paris: UNESCO, 2001; vol. IV: Science and Technology in Islam, Part 2, chap. 4-8.

[87] On Zeng He and his fleet, see Dreyer, Edward L. (2006). Zheng He: China and the Oceans in the Early Ming, 1405–1433 (Library of World Biography Series). Harlow, Essex : Longman.

? Levathes, Louise (1997). When China Ruled the Seas: The Treasure Fleet of the Dragon Throne, 1405–1433. Oxford: Oxford University Press.

? Ma Huan (1970). Ying-yai Sheng-lan, The Overall Survey of the Ocean’s Shores (1433), translated from the Chinese text edited by Feng Ch’eng Chun with introduction, notes and appendices by I.V.G.Mills. Bangkok: White Lotus Press. Reprinted 1997.

? Menzies, Gavin (2003). 1421: The Year the Chinese Discovered the World. New York: Morrow/Avon.

[88] This impact is competently outlined in W.M. Watt, The Influence of Islam on Medieval Europe, Edinburgh University Press, 1972, pp. 19-21.

[89] S.P. Scott, History of the Moorish Empire in Europe, op. cit., vol 3, p. 65. For a detailed account of the Islamic agricultural revolution, see D. R. Hill’s studies of the irrigation techniques in A History of Engneering in Classical and Medieval Times, London & Sydney: Croom Helm, 1984, pp. 17 ff.; idem, Islamic Science and Engineering, op. cit, pp. 170-186; A. Y. al-Hassan and D. R. Hill, Islamic Technology. An Illustrated History, op. cit., “Agriculture and food technology”, pp. 203-231, and Zohor Idrisi, The Muslim Agricultural Revolution, online at: https://muslimheritage.com/topics/default.cfm?ArticleID=515.

[90] See M. Schramm, Ibn al-Haytham’s Weg zur Physik, Wiesbaden, 1963 and Hakim Mohammad Said (ed.), Ibn al-Haytham, Hamdard National Foundation, Pakistan 1-10. November 1969.

[91] R. Rashed, “Geometrical Optics”, in Encyclopedia of the History of Arabic Science. Edited by Roshdi Rashed with the collaboration of Régis Morelon. London/New York: Routledge, 1996, vol. 2.

[92] Saleh Beshara Omar, Ibn al-Haytham’s Optics: A Study of the Origins of Experimental Science. Minneapolis: Bibliotheca Islamica, 1977.

[93] A. Pacey, Technology in World Civilization, op.cit.

[94] C. Singer (ed.), Studies in the History and Method of Science, Oxford, 1921; C. Singer, A Short History of Scientific Ideas to 1900, Oxford: Oxford University Press, 1959; C. Singer: Science: Medieval Contribution to Modern Civilisation, London: Harrap, 1921.

[95] S. P. Scott, History, op. cit., vol. 3, pp. 41-42.

[96] Ibid.

[97] Ibidem.

[98] See the excellent entry by Laurence Conrad, “Muḥtasib”, Dictionary of the Middle Ages, edited by Ioseph Strayer, New York: Charles Scribner’s Sons, 1989, vol. 9, p. 527. See also R. B. Buckley, “The Muḥtasib”, Arabica, vol. 39, 1992, pp. 59-117; Mawil Izzi Dien, The Theory and the Practice of Market lLw in Medieval Islam. A study of Kitāb Nisab al-Iḥtisāb of ‘Umar b. Muḥammad al-Sunāmī (fl. 7th-8th/13th-14th Century). Cambridge: E.I.W. Gibb Memorial Trust, 1997.

[99] L. Conrad, “Muhtassib”, op. cit.

[100] L. Conrad, “Muhtassib”, op. cit., p. 527.

*University of Manchester, UK; Chairman of Foundation for Science, Technology & Civilisation (FSTC), UK.

4.7 / 5. Votes 164

No votes so far! Be the first to rate this post.

Muslim Heritage:

Send us your e-mail address to be informed about our work.

This Website MuslimHeritage.com is owned by FSTC Ltd and managed by the Foundation for Science, Technology and Civilisation, UK (FSTCUK), a British charity number 1158509.

© Copyright FSTC Ltd 2002-2020. All Rights Reserved.